dedicated cardboard container creator what role do expert cardboard box makers have in improving packaging sustainability?

Explore the intriguing domain of corrugated carton production with this comprehensive guide. This overview highlights the important actions in altering basic fibers into solid boxes that shield products during delivery. Incorporating flute crafting, printing, and finishing, we discover the subtleties of this important domain.

- Identify the varied models of corrugated carriers and their special uses.

- Analyze advanced methods in container creation.

- Analyze the ecological implications and sustainable options.

Whether being an academic, specialist, or field admirer, this explanation conveys meaningful expertise on the fluctuating container manufacturing area.

Creating Innovations from Corrugated Sheets

Corrugated carton board, often unappreciated as basic packing item, works as a functional crafting element. Its durable quality enables the formation of innovative shapes and patterns, spanning useful organizers to fanciful embellishments. Using imagination, you have the power to modify this familiar fabric into everything remarkable.

Review the broad scope of corrugated carton board making by:

- Adopting various techniques such as slicing, bending, and layering

- Embracing recycled materials for an eco-friendly approach

- Presenting your projects to stimulate others

By virtue of its affordability, attainability, and adaptability, corrugated pulpboard satisfies artisans at any age and skill set. Unleash your inner designer and let your creativity flourish with this humble resource.

The Science and Craft of Cardboard Container Design

Corrugated container design combines a compelling fusion of engineering and design sensibility. It's not simply about constructing a box; it's about crafting a protective vessel that preserves goods throughout shipment while also making a memorable statement to buyers.

An experienced maker identifies the sophisticated qualities of corrugated carton board, adjusting its dimension, flute design, and layout to address distinct specifications of each asset.

- Additionally, design factors are vital.

- An expertly fashioned container is easily spotted on shelves, drawing attention from prospective customers.

- Essentially, box creation merges preservation and visual appeal.

Responding Needs: Enhancing Your Packaging Fabrication

During growth phases and expanding requests, it's important to secure capability for fulfilling consumer needs. Advancing packaging fabrication can help smooth running and preserve trustworthy reputation.

First, assess your current production capabilities. Examine available tools and personnel to locate potential blockages or zones needing enhancement. Subsequently, research ways to augment manufacturing scale. Reflect on obtaining updated technology or refining current gear to raise efficiency.

Consider that boosting volume is subordinate to enhancing full production line. Employ agile production models to cut waste and maximize input use. Improve procedures, robotize routine functions, and dedicate to employee coaching to establish a skilled workforce.

At last, establish solid rapport with distributors to assure regular input streams. Applying these plans, you will competently raise box creation and meet surging purchaser expectations.

Advancements in Corrugated Technology

The packaging industry is constantly evolving, driven by the need for sustainable, efficient, and innovative solutions. Corrugated carton board, a dependable material for ages, undergoes resurgence fueled by pioneering developments. From sturdy frameworks to connected components, corrugated sheets accept future technologies. Manufacturers are exploring new ways to enhance the performance of corrugated packaging, incorporating eco-friendly materials and processes. The impact is a tide of original packaging proposals changing the commercial terrain.

These developments tackle major obstacles confronting enterprises, including minimizing refuse and streamlining distribution. Shoppers also take advantage of these developments, using packaging that is tougher and more practical. The future of corrugation is bright, filled with potential to create a more sustainable and efficient packaging ecosystem.

Green Corrugated Boxes: Sustainable Solutions

Corrugated cartons constitute a fundamental component of contemporary logistics. Conventionally composed of material, these boxes hold considerable effects on ecology. Still, mounting understanding of sustainable tactics covers the creation of container items. Happily, novel techniques are provided to boost ecological soundness of similar packages.

An important element involves employing reclaimed cardboard. By applying industrial or household refuse, the requirement for new materials lessens, protecting ecosystems and natural wealth.

Furthermore, manufacturers are investing in sustainable production processes. This strategy incorporates maximizing power savings and decreasing surplus throughout operations. Shoppers can participate by picking containers endorsed as earth-friendly. Check for marks such as FSC or SFI that confirm accountable sourcing and fabrication.

By embracing these practices, we can ensure that corrugated boxes remain a vital part of our economy while minimizing their environmental footprint.

Guaranteeing Flawless Corrugated Cartons

Accomplishing prime fabrication in packaging construction depends on comprehensive quality checks. Starting at resource procurement and finishing with final product review, every process calls for persistent care. Severe controls manage fabrication stages to warrant every shipment matches highest measures.

- Assessing input components for imperfections, toughness, and regularity is essential to mitigating later difficulties.

- Respecting precise proportions and thresholds in trimming and molding ensures cartons are structurally robust and apt for purpose.

- Routine checking of print execution ensures striking graphics and legible scripts

- Implementing automated quality control systems can enhance efficiency and accuracy in the inspection process

Through emphasizing inspection throughout production, creators provide cartons that are long-lasting and attractive. Such commitment to high standards meets client demands and reinforces company image.

Packaging Branding: Visual and Impact

Container label printing serves as a crucial element of brand identity. When buyers view your goods, the packaging acts as a key tool for leaving an impact. An expertly crafted graphic on a carton can captivate interest, express brand personality, and drive buying choices.

Besides, packaging branding furnishes numerous ways to customize your shipments. By means of striking pigments to original graphics, you can demonstrate brand personality through carton design.

Therefore, packaging printing exceeds mere function – it serves as a potent method to enhance brand visibility and resonate with customers.

From Original Resources to Completed Articles: The Corrugated Container Operation

The fabrication of a container is an absorbing operation transforming elementary materials into a necessary shipment and packaging device. The procedure kicks off with supplying pulp, generally sourced from reused elements. This pulp is then transformed into sheets of corrugated board, featuring a fluted center layer sandwiched between two flat linerboard layers.

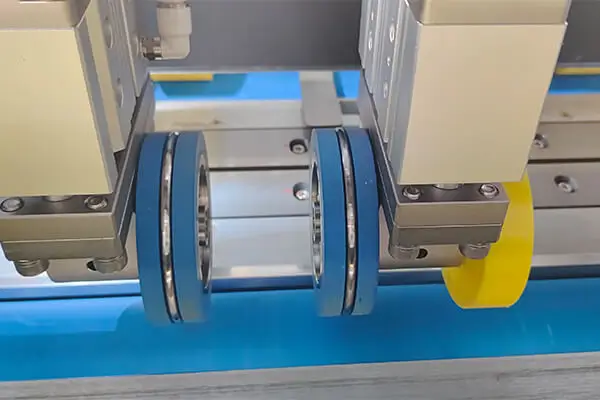

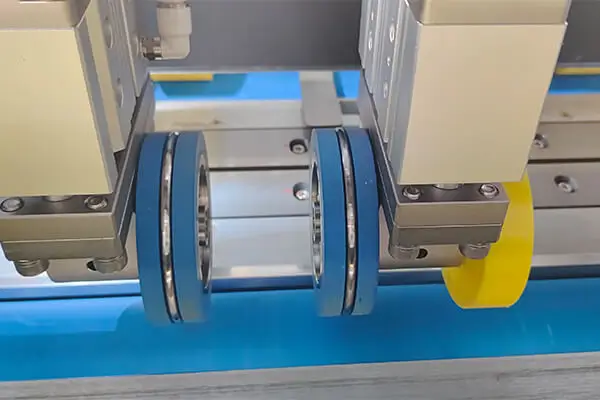

These sheets are scrupulously formed following strict dimensions, then unified by professional machines to make the preferred box structure. Tapes perform a vital part in uniting components firmly, ensuring a stable and durable assembly.

Finally, products undergo stringent inspection processes to secure strength and adherence to market standards.

From its humble beginnings, the corrugated box emerges as a versatile packaging marvel, ready to protect a wide range of products during transportation.

Global Packaging Industry: Trends and Openings

The global container market corrugated box maker faces a time of increase. This vibrant field is driven by increasing buyer requirements for protection. Core drivers encompass growth of digital retail and need for eco-friendly parcels