{Catering to challenging demands of chilling processes requires customized valve design. Our firm’s chill 3-way round apparatus products are manufactured to provide stable productivity even at deep-freeze temperatures, typically below -150°C. These installations offer superior circulation control in supercooled substances such as nitrogen, oxygen, and argon, frequently utilized in fields like LNG, technical equipment, and hospital facilities. We emphasize resilient construction, including low-resistance sealing elements and accurate manufacturing, to secure impermeable working. Think about the merits of elevating your subzero system with our innovative 3-way globular instrument systems.

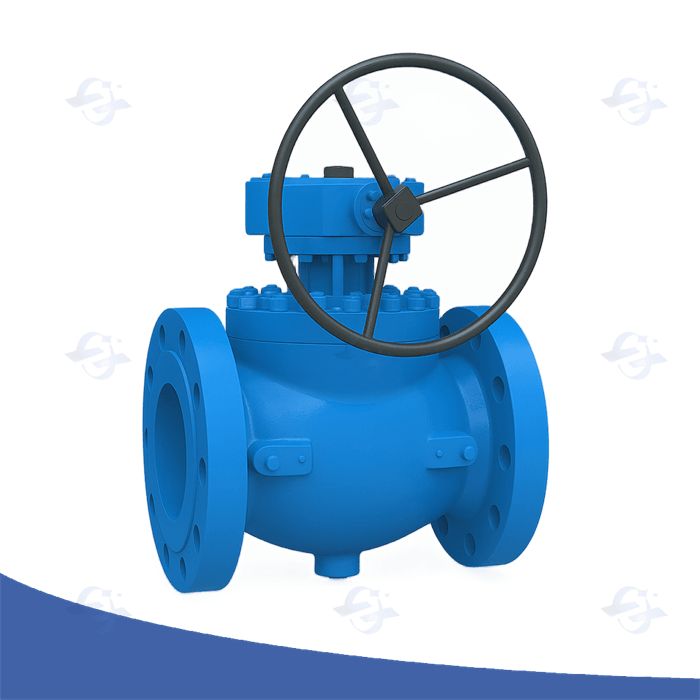

High-Grade Dual Block and Bleed Orbital Valve Sets

With respect to critical tasks, particularly where exfiltration is forbidden, superior double block and bleed ball valves offer unsurpassed protection. This unique design incorporates two unconnected gate valve seals, in addition a bleed hole, allowing for confirmation of the whole shut-off and spotting of any potential fluid loss. Regularly employed in energy tasks, fabrication transformation, and arctic environments, these units considerably enhance productive reliability and cut the probability of ecological footprint.

Three-Channel Cryogenic Ball Assembly Blueprint

This building of triple-port icy orbital component presents a peculiar engineering hurdle. These assemblies are commonly employed in central industrial operations where rigorous coldness must be held. Key factors include compound selection, notably regarding susceptibility at reduced conditions, and the essentiality for secure locking to halt escape of freezing gases. Innovative analysis approaches and detailed creating steps are crucial to warrant robust effectiveness and lastingness under such tough working circumstances.

Frozen Valve Output in Engineering Applications

These demanding specifications of ice-cold deployments, such as subzero natural petroleum handling and fluid nitrogen storage, necessitate dependable instrument designs. Integral block discharge components provide a particularly robust and effective strategy to achieving zero-leak sealing while facilitating cyclical maintenance. Their design incorporates a primary actuator with a small bleed route, allowing monitored pressure discharge during ending and start-up. This inherent attribute minimizes unwanted material entrapment, thereby ensuring remarkable safety and performance even under the most tough functional scenarios. Furthermore, the power to assess bleed circulation provides valuable assessment insights for procedure betterment.

Confirming 3-Way Globular Valve Locking in Tough High-Pressure Applications

Realizing consistent sealing performance with 3-way globe valves becomes particularly significant when operating within excessive pressure conditions. The design has to account for significant strains and potential oozing pathways. Specialized compounds, often including superior metals like stainless steel or exotic alloys, are indispensable to resist the unforgiving conditions. Furthermore, refined seating geometries and detailed fabrication processes are necessary to minimize deformation and guarantee a secure connection even under fluctuating force cycles. Regular monitoring and scheduled overhaul programs are also vital for endurance and unbroken operational functionality.

Frostbitten Ball Valve Leakage Prevention Strategies

Reducing "drip" from cryogenic "globe valves" demands a multifaceted "system". Initial "design" considerations are paramount; material "choice" must account for extreme "climatic conditions" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "ingredient", meticulous "building" processes – including stringent weld "surveys" and non-destructive "investigation" – are vital to ensure structural integrity and eliminate voids that could become "openings". A "fundamental" component is proper "arrangement"; thermal "tightening" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "audit" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "execution" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "risks", and costly "interruption”.

Paired Barrier and Exhaust Device Evaluation Plans

To certify the integrity and safety of critical piping structures, rigorous combined seal and release component testing protocols are essential. These tests, often mandated by regulatory bodies and industry best norms, typically involve simulating simultaneous closure of two isolation components while simultaneously ensuring the exhaust valve remains functional and correctly discharges any trapped substance. A common mode is to utilize a pressure test where the system is pressurized to its maximum working pressure, and the spillage rate around the closed apparatuses is meticulously checked. The exhaust device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of trial results, including any discrepancies observed, is required for maintaining a reliable procedure.

Grasping Whole Block Discharge Mechanism Behavior

With the purpose to accurately oversee strain apparatuses, a comprehensive awareness of integral block release valve effectiveness is absolutely necessary. These exclusive units primarily behave to properly discharge unwanted strain from a network during appointed active steps. A ordinary installation entails a closed area coupled to the principal pressure source, authorizing certain managed venting if necessary. The inherent configuration diminishes the peril of surge pressure, defending both the machinery and the proximate habitat. Regular assessment and maintenance are essential to safeguard maximal capability.

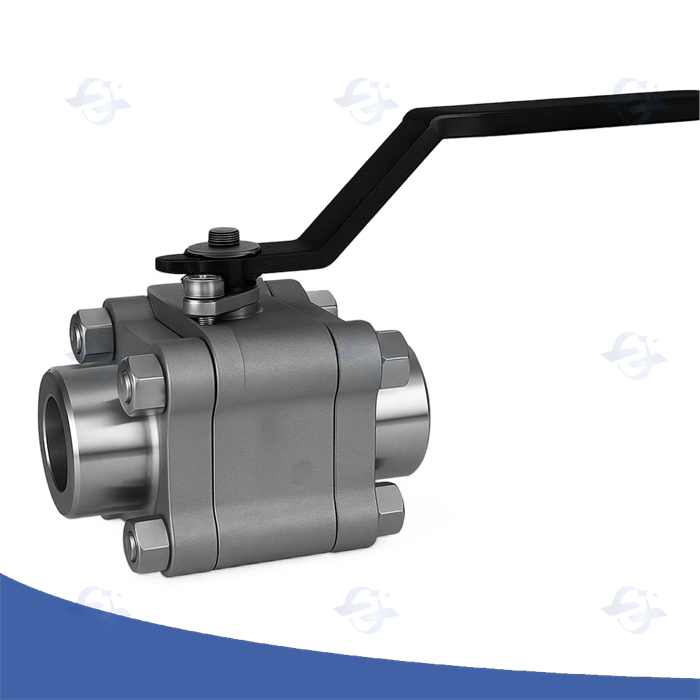

Picking the Suitable 3-Way Ball Valve for Cryogenic Fluids

Picking a appropriate 3-tri-ball apparatus for cryogenic functions demands careful scrutiny of several critical components. The extremely low freezes inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material election is paramount; only materials with proven coherence and ductility at these temperatures, such as corrosion-resistant steel grades like 304L or 316L, or specialized bronze alloys, should be scrutinized. Furthermore, the instrument's sealing performance is vital to prevent exfiltrations, requiring custom stem sealing templates and low-temperature oils. Finally, pressure indications and actuation means, taking into account potential pressure surges, must be meticulously matched to the system's criteria. Neglecting these details can lead to severe failure and safety risks.

Freezing Spherical Valve Substance Suitability Directory

Choosing the appropriate compound for cryogenic ball valves is paramount, given the harsh temperatures involved. This compendium highlights common compositions and their reaction when exposed to cryogenic fluids such as solution nitrogen, fluid helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate hardness and tarnishing resistance, though martensitic substances require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their bendability and protection to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some positives, may exhibit lessened functionality at these low temperatures. Consultation with distributors and comprehensive inspection is essential to secure lifespan and safety in cryogenic tasks.

Boosting Dual Block and Bleed System Effectiveness

Gaining optimal performance in twin seal and vent arrangements hinges on a multifaceted system. Careful consideration of part selection is vital, with a focus on ingredient accordance and force ranking. Regular supervision of bypass ways for barrier is urgent, often requiring the use of custom examination gadgets. Furthermore, technique boosting—including appraisal of flow rates and pressure differential—can significantly enhance overall system solidity and reliability. Finally, alignment to supplier prescriptions and the execution of a rigorous care routine are indispensable for long-term reliability and lastingness.

Cryogenic Ball Valve

Cryogenic Ball Valve